Authentic Bavarian shorts are made following some steps, from selecting the leather to tanning and cutting the leather to stitching it skillfully into authentic Bavarian shorts. The process results in the trachten shorts, the heart and soul of Oktoberfest and other Bavarian celebrations.

The same process has been used for centuries to manufacture lederhosen, resulting in authentic traditional Alpine shorts. Over time, the lederhosen evolved into the distinctive style we know today, becoming synonymous with Oktoberfest celebrations and Bavarian folk culture. Today, custom lederhosen best serve as a souvenir, like Tom Brady's custom Bucs Leather shorts.

Step by Step Lederhosen Manufacturing

Authentic leather breeches require several steps. Understanding these steps helps us appreciate the skill required to create these traditional pieces of art.

Step 1: Selecting The Right Leather

Different types of lederhosen depend on the leather used in manufacturing the Bavarian leather breeches. Some of the most common types of leather used as material for crafting lederhosen are;

-

Cowhide Leather

-

Goatskin leather

-

Deerskin leather

Characteristics of Different Leathers

All the different types of leather have distinct characteristics and are chosen because of these peculiarities.

Characteristics of Cowhide Leather Traditional Alpine Shorts

-

Cowhide is listed amongst the toughest animal-sourced leather with strong fiber bonds.

-

Its thickness contributes to its durability and weight, making it less stretchable than other leathers.

-

Highly resistant to wear and tear, thus great for lederhosen.

-

Cowhide leather becomes waterproof when treated and adequately waxed. This property makes it ideal for adverse weather conditions.

-

It provides good insulation, making it ideal for protecting against cold or harsh conditions.

-

It is affordable yet less supple compared to the goatskin and deerskin leather breeches.

Characteristics of Goatskin Leather for Lederhosen

-

It offers a strong yet lightweight option for lederhosen manufacturing.

-

It provides ease of movement and comfort while wearing.

-

Goatskin leather breeches have enhanced softness due to the presence of lanolin, making them pleasant to touch.

-

These leather shorts can be used in their natural form or dyed for a stylish and appealing look.

-

It is preferred for applications where appearance, texture, and softness are priorities.

Characteristics of Deerskin Leather for German Leather Pants

-

Lederhosen manufactured from deer hide offer exceptional softness, comfort, and a luxurious feel.

-

Deerskin leather breeches are naturally breathable.

-

These shorts combine softness with high resistance to mechanical forces for strength and longevity.

-

German tracht for men easily conforms to shapes and movements due to its natural flexibility.

-

It features a distinctive natural texture, because of which it is sold at a higher price range.

Step 2: The Leather Preparation for Manufacturing Lederhosen

The preparation of leather before cutting it into pieces to make the lederhosen is done in many different small steps.

Preparing the Raw Material

In the preparation of raw materials for leather production, hides arrive at the tannery. It is stored in the Beam House, preserved in rock salt, folded, and placed on pallets for up to 30 days.

The processing begins with the removal of salt by tumbling the hides with pegs that propel them forward, collecting and recycling the salt for further use. Haired hides bypass desalting and go straight to soaking drums for one to two days to rehydrate and remove dirt, salt, and soluble proteins.

In the next step, lime treatment removes hair, softens the hides, and enhances their quality. All hides are then defleshed to eliminate surplus waste from the backside. The hides, containing significant moisture and measuring approximately 4 mm thick, pass through a splitting machine that divides them into two layers.

The lower layer, or reticular segment, is used for lower-quality, inexpensive leathers often utilized in handbags and shoes. The upper layer, or papillary segment, is reserved for high-quality full-grain leathers featuring a tight fiber structure. This superior layer undergoes specialized retainage, offering luxurious suppleness, vibrant color clarity, a rich base dye, and a breathable protective finish.

|

Did you know? The yield of leather refers to the amount of usable product that can be cut from a hide. Several factors influence the yielding, including the hide's size and quality and the cutter's skill. Large hides with minimal defects and imperfections offer the highest yield. |

Tanning the Leather

Preparing raw materials for leather production involves a series of diligent processes to convert pre-tanned hides into high-quality leather. The primary tanning process preserves hides and halts decomposition by immersing them in a solution of chromium salts or vegetable tanning agents inside a tanning drum.

The drum rotates for up to eight hours, reheating the solution to ensure optimal penetration, softening, and preservation of the hides. Following tanning, fat liquoring adds natural bovine oils, enhancing the leather's strength and softness.

Types of Tanning Process

There are three main types of tanning process that are used;

|

Vegetable Tanning |

Chromium Tanning |

Chromium-Free Tanning |

|

-The oldest tanning method. -Uses natural extracts from the wood and nuts of trees and shrubs sourced. -Vegetable tanning requires more tannins. -It’s eco-friendly due to its use of renewable materials |

-It is termed “wet-blue” for its pale hue. It is trimmed of irregular edges and shaved to achieve uniform thickness. -Efficient use of materials is prioritized in the process. -Trimmings and shavings are repurposed for various products, such as bonded leather and floor tiles. -The practice highlights the industry's commitment to sustainability. |

-Chrome-free tanning involves specialized processes tailored to specific performance requirements, particularly in automotive applications. -Aldehyde tanning, the most common chrome-free method, uses glutaraldehyde to tan hides. -Additional chemicals are applied after tanning to enhance leather properties for specific uses. -Effluent from chrome-free tanning requires extra treatment to meet environmental safety standards before disposal. -Chrome-free tanning offers an eco-conscious alternative for industries prioritizing sustainability and specialized performance criteria. |

Dyeing the Leather

Dyeing is the process of adding color to leather. Tanneries use different dyes to create shades ranging from neutral tones to bright, saturated hues. A computer formulates dyeing recipes for precise color accuracy and consistency. The process for approximately eight hours.

A cutting is taken to confirm complete dye saturation, indicated by the remaining liquid in the drums turning clear. Once dyed, hides are either air-dried or vacuum-dried. After drying, the hides are staked to enhance softness and vaporized to restore moisture.

Finishing & Cutting the Leather

The finishing touches of the leather include minimizing the appearance of grain blemishes and glossing. The next step is the ironing process, in which heat and pressure are applied to achieve varying levels of sheen, with higher temperatures and greater pressure creating a more pronounced shine.

Before cutting the leather is finally inspected. The leather is then taken from the tannery to the workshops where the tracht is either handmade, customized lederhosen, or to factories like the way “Oktoberfest Lederhosen Shop” crafts their finest tracht.

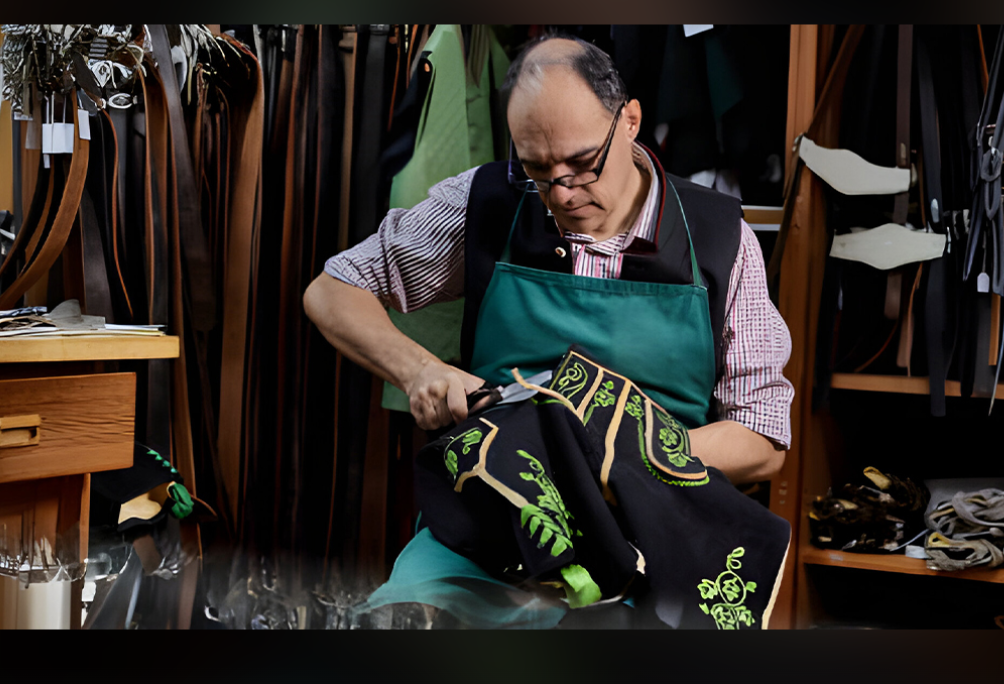

Step 3: Embroidering the Traditional Bavarian Motifs

Originally, Lederhosen did not feature embroidery. The upper class later introduced it as a fashion statement to display wealth and social status through intricate designs. Over time, embroidery became a cherished tradition, with specific motifs symbolizing Bavarian culture and values.

In authentic Lederhosen, traditional hand-embroidered designs are applied to specific areas like the front flap, reinforced pockets, and thighs. Common motifs include majestic stags symbolizing spiritual authority, playful edelweiss representing purity and love, the Bavarian coat of arms denoting courage and royalty, and oak leaves signifying justice, strength, and nobility.

The embroidery is crafted with gold or silver silk or cotton threads, highlighting the artistry and skill of the creator. Each design reflects precision and attention to detail, showcasing the craftsmanship that only a skilled professional can achieve.

Step 4: Hand Stitching the Lederhosen

Leather is a dense and durable material, requiring a specific needle and thread for sewing. While not all authentic Lederhosen must be entirely hand-stitched, it is advisable to hand-stitch key areas like the flap, inner seams, and pockets for added durability.

To create a premium Lederhosen piece that lasts for generations, follow these practices:

-

A medium-weight 90/14 needle and heavy-duty nylon thread is used for optimal quality.

-

A stitch length of 3 to 4 mm is maintained to prevent weakening the leather from excessive piercings.

-

The trousers are sewn together and the measurements are checked.

-

Finally, all seams are worked on again and evened out if necessary. Then the leather dust is removed and a final check is carried out.

|

Did You Know? The production time for embroidered short leather trousers is approximately 22 hours, while bundhosen take around 27 hours to manufacture. |

Step 5: Finishing Touches for Lederhosen Manufacturing

Quality assurance is essential in every industry, for crafting the highest quality end product. Skilled professionals carefully inspect each Lederhosen piece, focusing on testing the strength of every seam, monitoring the stitching consistency. The entire Lederhosen is inspected inside and out for blemishes, tears, or cuts.

Reinforced areas such as buttons, belt loops, and pockets are checked for proper placement. Once these quality control checks are passed, the Lederhosen are considered authentic and approved for their top quality.

The final step before the product is ready for wear involves applying natural oils, such as neatsfoot and mink oil, to enhance the texture and bring out its bold color, making it ready for occasions like Oktoberfest

Wrapping It Up!

Lederhosen making involves careful selection of leather sourced from animal hide and thorough quality checks at every stage. The treated leather is collected from the tannery, cut into pieces, embroidered, and stitched into final German leather shorts. The result is a durable, authentic garment ready for any occasion.

Buy your lederhosen manufactured by “Oktoberfest Lederhosen Shop”, check-marking every box of authenticity and traditions!